By Jenni Gritti Probst | Posted March 7th, 2025

At Perkins, we are committed to investing in optimised diesel technologies to ensure our customers receive the best in performance and efficiency. For decades, diesel internal combustion engines have been the backbone of a wide range of equipment, providing robust performance and reliability.

As we look to the future, diesel-electric integration combines the proven capabilities of traditional diesel engines with the efficiency and benefits of electric power. By combining diesel technology with electric systems, we are setting a new standard for performance and sustainability. And this year at bauma, we are excited to share details of our latest advancements in diesel-electric integration.

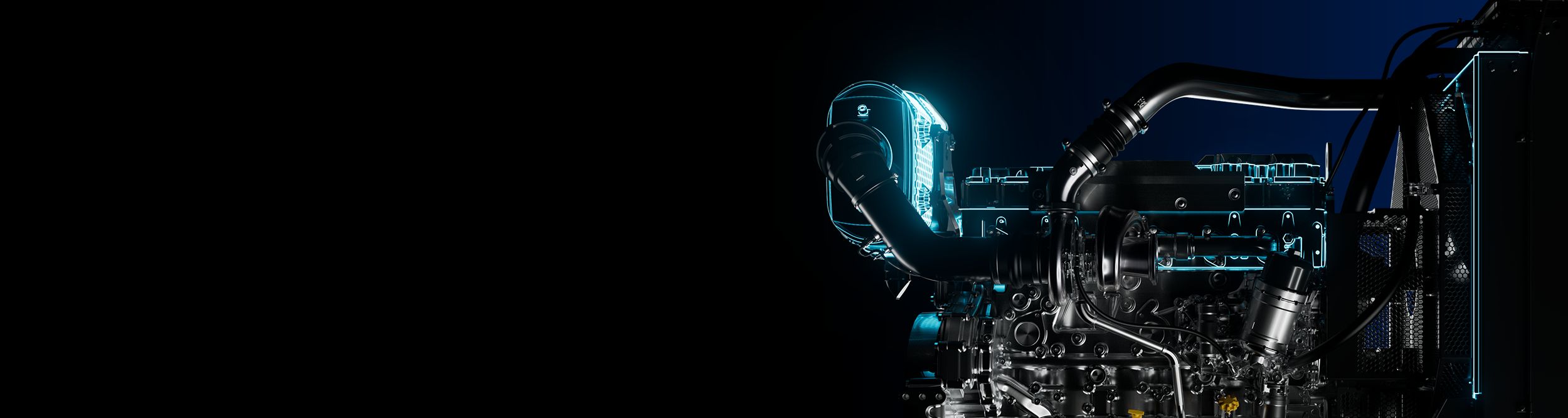

To demonstrate the effective use of hybrid technologies, our engineering teams have integrated a diesel-electric system into a telehandler. By combining the robust performance of a 904 Series diesel engine with the efficiency and benefits of electric power, Perkins is setting a new standard for telehandler capabilities. This hybrid approach not only reduces fuel consumption and emissions but also enhances operational flexibility, allowing for electric-only running in specific scenarios, such as indoor operations.

Our recent work exemplifies this innovation. By converting a 75 kW diesel-powered telehandler into a hybrid machine using a Perkins® 48V battery electric system and 55kW 904J-E28T diesel engine, we have demonstrated the potential of hybrid technology to transform traditional machinery. This conversion enables electric-only running capability, which is particularly beneficial for indoor operations where zero-tailpipe emissions are crucial.

For original equipment manufacturers (OEMs), the benefits of integrating diesel-electric systems into telehandlers and many other applications are clear. Lower fuel consumption and reduced emissions translate into cost savings and compliance with increasingly stringent regulations. Additionally, the ability to operate in electric-only mode opens up new possibilities for machine usage, particularly in environments where noise and emissions are a concern.

Perkins' hybrid technology is designed to integrate into existing machinery without the need for extensive redesigns. This approach minimises disruption and allows OEMs to quickly and efficiently upgrade their fleets. Our hybrid systems are also built to the same high standards proposed for OEM offerings, ensuring reliability and performance in the field.

At bauma 2025, we will be discussing how our hybrid power units and electrified machinery can transform your operations. Our experts will be available to share insights on the latest advancements in hybridisation and electrification, and how these innovations can help you achieve your sustainability goals while maintaining operational efficiency. Because together, we power ahead.

Contributor

Not one to walk away from the chance to tell a good tale, Jenni spends her days crafting and sharing stories of the people, products and services that make the world a better place. When she’s not working her dream job at Perkins, she’s usually outdoors hiking, exploring, and playing in the dirt.

Discover Perkins' Innovative Power Concepts at bauma 2025

Read moreExploring the Future of Energy: BTL, GTL, and Perkins Engines

Read moreWhat is HVO fuel and why should I consider it as an alternative to diesel?

Read morePerkins 2606 Engine: High-Performance Power Solutions for Electric Power

Read moreCompact Power: The Benefits of a Smaller Engine with Greater Displacement

Read more