Highly efficient and able to handle abrasive liquids and turbid sandy waters, Atlas Copco’s newest portable pumps are at work keeping job sites dry and projects on schedule all over the world. Efficiency and the ability to respond to a broad range of power requirements are prime reasons Atlas Copco chose Perkins® 904J-E36TA engines to power their PAS 200 HF and PAC F88 vacuum prime centrifugal pumps.

“We have used this engine for a specific reason,” said product marketing manager Andreas Neufeld. “A pump core consumes a certain amount of power and requires torque at specific speeds. So, the Perkins 3.6 litre engine, with its specific configuration, was matching perfectly our demand on the pump side.”

In the power range required by the PAS 200 HF and PAC F88 pumps the engine meets U.S. Tier 4 Final and EU Stage V emission standards using a Diesel Exhaust Fluid (DEF) system instead of a Diesel Particulate Filter (DPF) in combination with the catalyst.

“That’s important,” Andreas noted, “because we run these pumps in various speeds, so there is a different engine load demand based on the operating duty point. How much water do we have to pump? How far and what elevation do we have to overcome. All these parameters have an impact on the engine load performance.”

The compact, power dense, 3.6 litre Perkins 904J-E36TA also helped Atlas Copco reduce the height of their new pumps making it easier for operators to manage pipes and connections. The low profile also makes the pumps easier to tow and even increases performance because they gain an extra bit of suction lift by being closer to the ground.

Want to know more? Read the full case study.

The new Ronggong RG-8240 is a multifunctional road sweeper powered by a Perkins® 404D-22.

Read moreWeiman uses the Perkins® 400 to 4000 Series range in its generator sets.

Read moreCaptiva's generator sets from 400 to 2500 kVA are powered by Perkins® 2000 and 4000 Series engines.

Read moreMeeting the need for electric power in areas of Ukraine with unreliable or unavailable grid power.

Read moreWith outputs from 10 kVA up to 2250 kVA, PowerLink generator sets meet a broad range of prime and standby power needs.

Read moreQuiet Perkins engines power Supernova’s large generator sets.

Read moreIraqi hospital relies on Perkins powered generator sets.

Read moreGiant remote oil field depends on Perkins powered generator sets.

Read morePerkins power is at the foundation of global construction projects.

Read moreSupernova Generators re Alembic Pharmaceuticals.

Read moreLega Power standby generators depend on Perkins’ power and global support.

Read moreWestinpower has supplied over 15,000 Perkins-powered generators to their customers since 2003.

Read moreAGG relies on Perkins to power their standby and backup power systems in more than 80 countries.

Read moreCaptiva Energy Solutions’ Perkins-powered backup generators keep silicone production flowing at Wacker Metroark in India.

Read moreCaptiva Energy Solutions supplies reliable back-up power for Ambuja Neotia in India.

Read moreGenerac Mobile chooses Perkins power for their new mobile generator sets.

Read moreSullair sets high standards with its air compressors as construction projects depend on them to be successful.

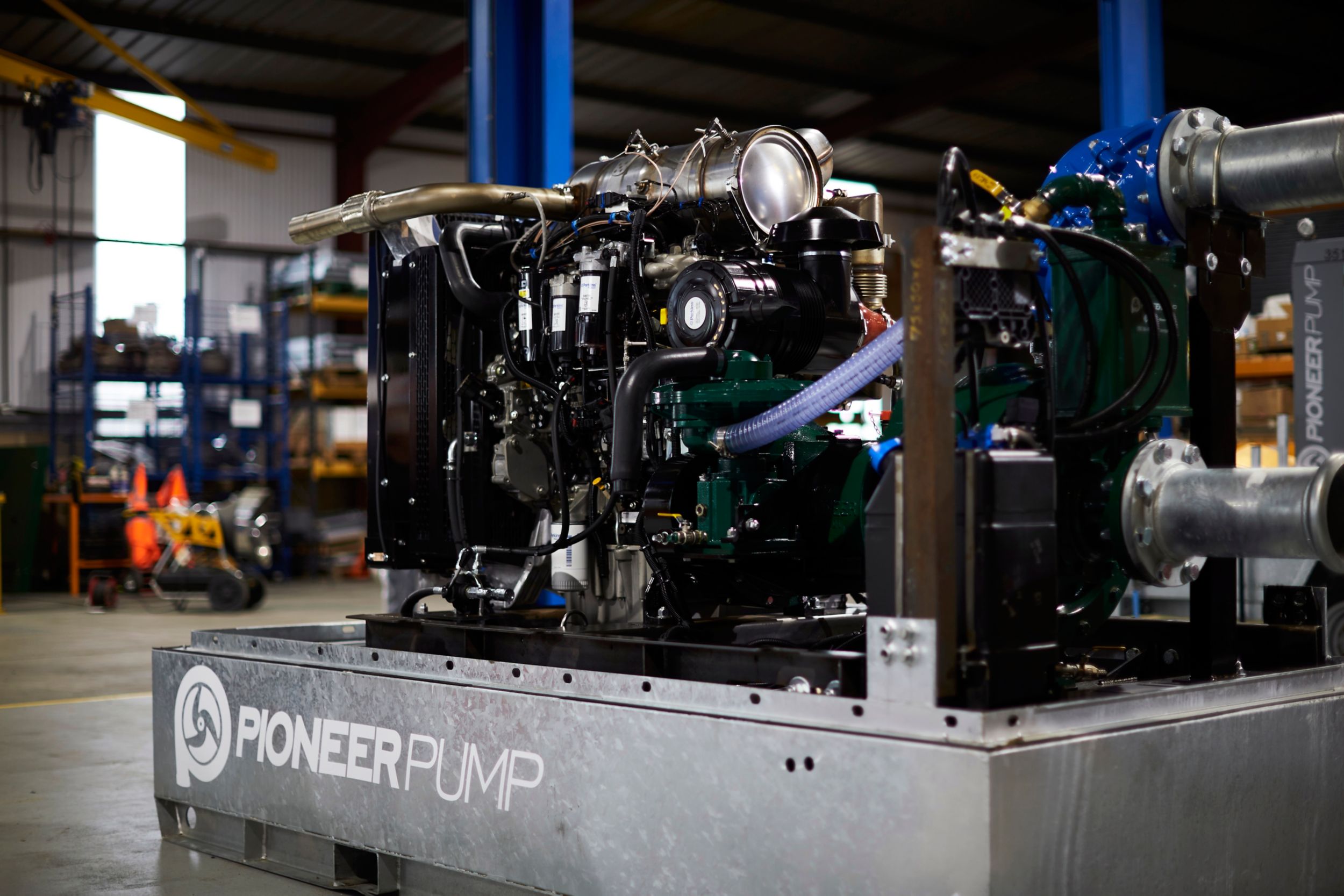

Read moreGet pumping with Pioneer Pump’s proven workhorses which are trusted to dewater and transfer water.

Read moreMPMC POWERTECH CORP provides the power, when it’s needed, to its global customer base.

Read moreTaylor Power Systems provides the standby power to enable a steady water flow.

Read moreXuzhou Construction Machinery Group Co., Ltd. provides solutions for sustainable development.

Read moreFusing pipes conveniently and quietly

Read moreHeavy lifting with dependable performance

Read moreKeeping job sites bright and running 24/7.

Read moreLincoln Electric’s new Vantage 441X welder/generator.

Read moreAJ Power and Perkins join forces to keep data flowing.

Read moreA workhorse for any fleet.

Read morePower generation that saves lives.

Read moreKeeping workers warm on the jobsite.

Read moreReliable prime power for mining operations.

Read moreDelivering performance, efficiency and reliability.

Read morePumping concrete higher, further and faster.

Read moreSaving lives, one load at a time.

Read moreWay Industries upgrades its skid steer loaders.

Read moreDelivering diesel-powered generators to an exact customer specification.

Read moreEngineered for an all-terrain performance.

Read moreCollaborating to deliver a new Stage V powered combine.

Read more