Every Perkins engine is designed with longevity in mind. Add to that the regular servicing and maintenance, and use of genuine Perkins parts, and your Perkins engine is set to run for many thousands of hours.

But it’s only to be expected that with that kind of pedigree, some engines will have more asked of them than others: heavier use, or continuous operation in difficult conditions, for example. In these cases, it’s the core of the engine that can bear the brunt of the action.

While this isn’t an area that’s included in routine maintenance, it can be addressed with a routine engine overhaul. Just one single part number is all that’s needed to order one of a new range of overhaul kits for six-cylinder Perkins® 2000 Series engines, providing a simple, cost effective solution to restore an engine to its ‘as-new’ performance potential.

Each kit includes all the genuine Perkins parts needed to perform progressively complex levels of service, ensuring perfect fit and optimum performance, supported by a 12-month Perkins warranty to offer peace of mind and protection.

By overhauling rather than replacing, the kits not only offer a money-saving route – up to 50 per cent compared to the cost of a replacement engine – but also meet ESG objectives by minimising the raw materials and energy required to produce new parts.

“Perkins engines are built for the long haul, offering industry-leading performance, reliability durability and value,” says Richard Hemmings, Perkins aftermarket general manager.

“Our new overhaul kits for the Perkins 2000 Series allow equipment owners to select the precise mix of components they need to revitalise their engines and achieve even greater returns on their investments.”

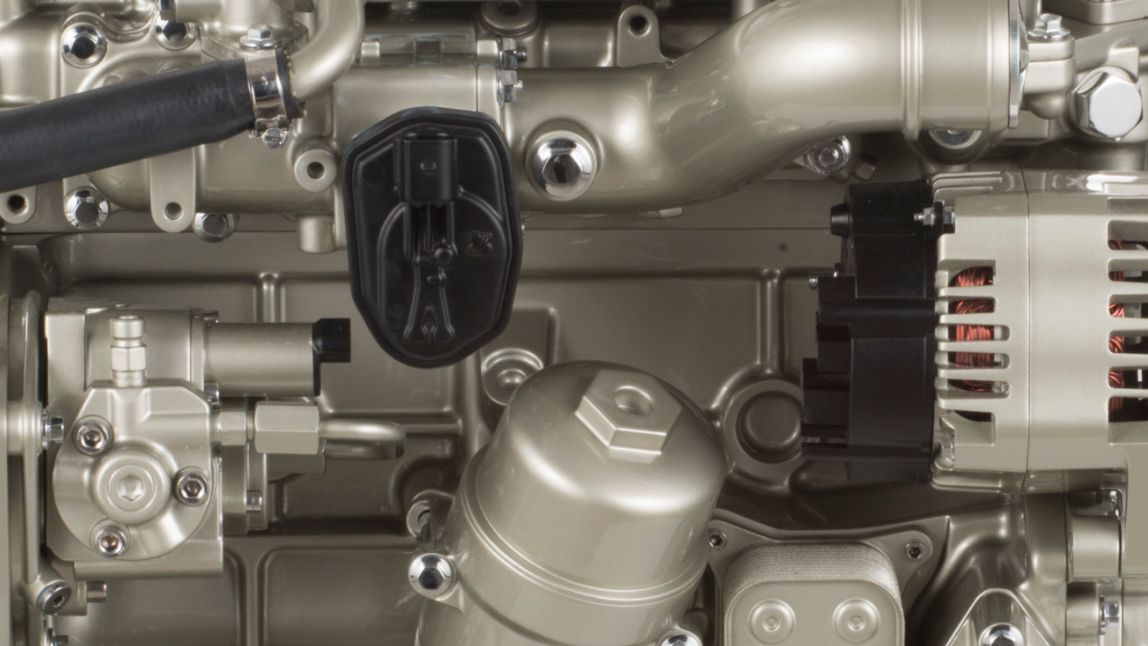

Suitable for 13-, 15- and 18-litre 2000 Series engines offering power output from 358 up to 470 kW (480-630 horsepower), the new overhaul kits for Perkins 2000 Series engines include gaskets, seals, filters, regulators, belts, pistons and rings, valves, sleeves, pumps, injector components, springs and other parts, depending on the package selected.

Operators can choose from four packages, according to the intensity of overhaul required:

Selecting the appropriate overhaul kit for an engine relies on running time and current condition. Your engine’s Operational Maintenance Manual, plus advice from a qualified technician, will help you make use of the correct kit.

The new overhaul kits for the 2000 Series continues the longstanding Perkins commitment to engine longevity and return on investment. Basic overhaul kits are still offered for the company’s extensive range of heritage engines, as part of a range that also includes kits for the 400, 1000 and 4000 Series engines.

Advanced connectivity and condition monitoring marks a new era in equipment management.

Read morePowernews caught up with BUPS distributor principal, Franz Focks, to learn more about its work with customers.

Read moreOur global network of 80 Perkins distributors have a ‘think global, act local’ approach.

Read moreTheir story includes more than 20,000 generator sets powered by Perkins engines.

Read moreBuilding on the Perkins legacy in Brazil.

Read moreExtending the life of Perkins® 1100 Series engines.

Read morePerkins Latin American agricultural initiative is breaking new ground.

Read moreSecodi: providing quality power and end-to-end service for 45 years.

Read morePTTN has been the authorised Perkins distributor since 1976.

Read moreWe talk to the owner, founder and chairman of Supernova Engineers Limited.

Read moreProviding full value and the most worry-free ownership experience possible.

Read moreWe talk to the founder and CEO of Captiva Energy Solutions.

Read moreListening to our customers creates better solutions.

Read morePart four of our 'Engines that made Perkins'.

Read moreThey're easier to control than you may think.

Read moreRestoring the portrait of Frank Perkins

Read moreInterview with engine enthusiast Jeffrey Giblin.

Read moreA distributor is more than a place to buy parts.

Read morePerkins heritage - part 3: focusing on the 1000 Series.

Read moreEmployees share their thoughts on the brand and how it supports its customers.

Read moreRefurbishing, overhauling or rebuilding your Perkins engine just got easier.

Read morePerkins is committed to sustainable manufacturing at every one of its global facilities.

Read moreThe 4.236 and 3.152 engines cemented Perkins’ position as ‘the’ farming diesel engine.

Read moreSince 1932 over 22 million diesel engines have rolled off our production lines, initially from the Peterborough, UK, factory and now from facilities around the world.

Read moreMeet Kajsa Mildén, a businesswoman with multi-industry experience, and the current CEO of Universal Power Nordic, our distributor for Sweden and Norway.

Read moreThe basic principle of fuel injection is the right amount of fuel must be injected at the right time to satisfy horsepower demands.

Read moreYour engine is in the capable hands of the Perkins distributor network, meaning access to trained technicians, genuine parts and a customer focused business approach.

Read moreA diesel engine is an amazing piece of engineering.

Read moreOur top tips to keep your engine running when it's cold.

Read moreToday's diesel engines are different from previous generations. Test your engine knowledge.

Read moreThere's a lot more to coolant than water and antifreeze.

Read moreGet the most from your low-emission diesel engine.

Read moreThere are no ordinary days for a Secodi technician.

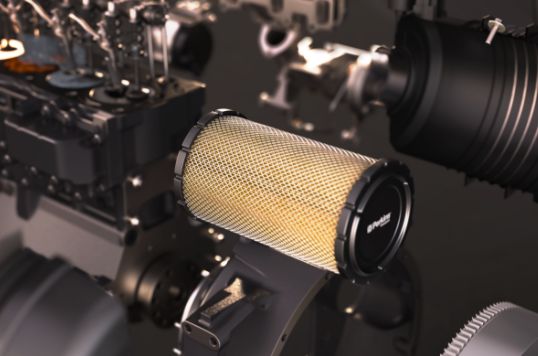

Read moreFiltration - the key to protecting your engine investment.

Read morePerkins fluid sampling - delivering a new level of engine insight.

Read moreWhen a customer needs service, PTTN delivers - no matter what.

Read moreOur global network of 80 Perkins distributors have a ‘think global, act local’ approach.

Read moreTheir story includes more than 20,000 generator sets powered by Perkins engines.

Read moreBuilding on the Perkins legacy in Brazil.

Read more