Unscheduled downtime during the ‘frantic’ periods can be devastating to growers since it means either crops aren’t planted or aren’t harvested on schedule. The cycle also creates a major challenge for original equipment manufacturers (OEMs), their supply chains and support networks who have to deliver the parts and services needed to keep the equipment working.

As a major supplier of engines for tractors built and used in Latin America, Perkins has encountered this challenge while supporting both OEMs and end users through their parts distribution and authorised distributor networks. However, unlike some suppliers who simply view the issue as a normal part of doing business, Perkins chose to address it proactively and develop a solution.

“Our medium engine programmes have been very successful here in Brazil,” explained Rafael Souza, marketing manager for LATAM. “Virtually every OEM we have worked with to develop an engine solution now offers a Perkins powered tractor in this size range.

“Significant portions of that fleet are now reaching 3,000 to 4,000 hours of usage and that’s when things often begin to wear out and need replacement. So, it was time to get ahead of the issue rather than waiting for it to manifest.”

To implement a successful solution that had encountered similar challenges, technical expert Marcelo Costa found out more about a pilot programme that had been run and tested within the wider Enterprise in the U.S. Pacific Northwest with strong positive results. That programme had combined pre-frantic period engine inspections with a dealer seasonal part stocking initiative based on historic usage patterns.

“The idea,” Marcelo said, “was to identify and remedy potential equipment problems before the intensive use period and also make sure routine maintenance was being performed. That way major issues could be addressed during normal downtime and a machine wouldn’t be sidelined for something like an oil or filter change when it was needed in the field.

“The second part of the programme made sure that parts that commonly needed replacement during the ‘frantic’ periods were pre-positioned on local shelves for timely delivery. That could make the difference between a few hours of downtime and a few days waiting for parts to arrive from a distant warehouse.

“The programme was a win-win for everyone involved. End users achieved more uptime during ‘frantic’ periods. Dealers and distributors built customer satisfaction and loyalty with timely delivery of parts and service. And, the OEM fortified their reputation for reliability and dependable customer support.

“While the North American programme offered the framework for a viable solution,” Marcelo said, “there are significant differences in the agricultural practices in the two locations that had to be taken into account.”

For example, North America generally plants two crops annually, while warmer Latin America tends to plant three. Latin American crops also tend to vary more from region to region than is typical to the north.

Moreover, the Perkins powered tractors used in Latin America typically are used with a much larger variety of implements to perform a greater range of tasks than their North American counterparts. That places different demands on the engines and complicates maintenance and service requirements as well as impacting part wear characteristics.

“There also are purely local issues in Latin America and particularly in Brazil,” Rafael added. “One of the big ones is the growing use of Biodiesel and the changing legal requirements surrounding it. That makes it difficult for end users to stay abreast of best practices and the result is all too often a damaged engine.

“It’s hot in Brazil, and storing fuel with a portion of Biodiesel in a black tank under the sun when it’s 40° C (104° F) is definitely not a best practice. Nevertheless, it’s often done. Water contamination also is a common issue that often leads to injection pump failures.”

With these differences in mind, Marcelo invited a team of individuals who had created the North American programme to Brazil to work with Perkins, local distributors and OEM tractor manufacturers to develop a solution for Latin America. The manufacturers were included because their secondary dealer locations frequently are the initial contact points for end users.

“In Latin America, Perkins authorised distributors aren’t the only organisation supporting end users of our engines,” Rafael explained. Without buy-in from the OEMs and their secondary dealer organisations the programme wouldn’t be able to achieve the kind of reach we envision. The goal is to duplicate the results achieved in the pilot programme while fully addressing the differences in the Latin American market.”

Perkins distributors have responded to the new programme enthusiastically. One major customer will be presenting the programme to their dealer and secondary dealer networks at their annual meeting in Q4, 2023. Others have indicated similar intent to implement the new capabilities in the near future.

“Customer support always has been a major focus at Perkins,” Rafael added. “As we powered more and more Latin American tractors we recognised the need to implement innovative new support strategies. This agricultural support initiative is the next step, but I can guarantee it’s not the last. Our customers demand constant improvement, and we’re determined to meet the challenge.”

Why stick to one fuel, when you can have a configurable power system?

Read moreMore than just a curiosity, they offer us different routes to future food security.

Read morePerkins marine engines has an illustrious history. Meet the team behind the brand.

Read morePower systems, services and technologies engineered for efficiency, productivity and fuel flexibility will be on show.

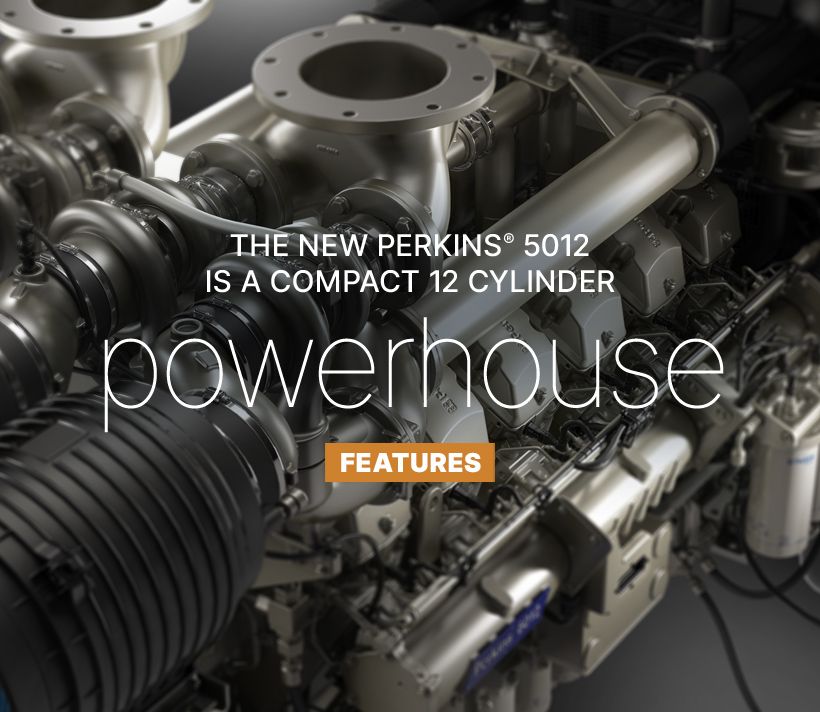

Read moreDelivering dependable prime and standby solutions with the 13 litre 2606 and a 46 litre 5012.

Read morePerkins has announced a power uplift to the popular 3.6 litre variant.

Read moreWe chat to Corey Berry following the successful showings at American Rental Association (ARA) and United Rentals exhibitions.

Read moreWe headed to Malaga, Spain, to learn more and see the machine in action.

Read moreWhat might the coming months hold? Powernews does some opinion legwork, so you don’t have to.

Read moreThe Perkins marine distributor network is there to service customers of Perkins anywhere in the world.

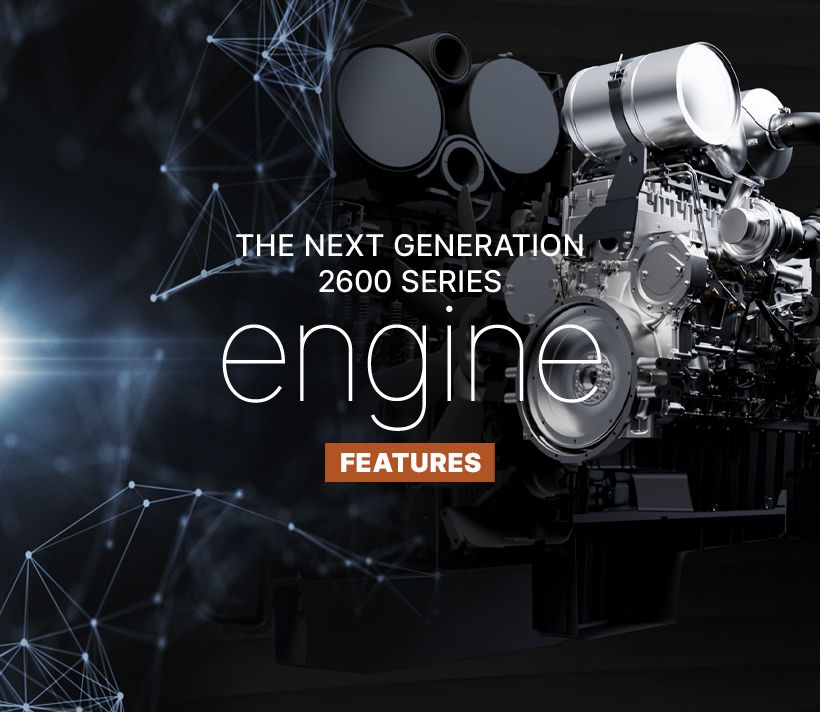

Read moreAvailable in the second half of 2025, the 2600 Series offers excellent load acceptance, fuel efficiency and versatility.

Read moreHow our Customer Solutions and Engineering teams are actively helping customers reduce fuel consumption.

Read moreThe state’s farmers grow more than 400 commodity crops, 19 of them unique to the Golden State.

Read moreMore than 280,000 visitors from across the world attended this year’s four-day long Bauma China exhibition in Shanghai.

Read moreWe follow the journey from a Perkins facility in the UK to installation on a passenger ferry in Singapore.

Read morePowernews caught up with Sylvia to learn more about her responsibilities, motivations, and leadership journey.

Read moreA new range of auxiliary marine engines were shown at METS.

Read moreAdrian Bell dives into the history of Californian agriculture.

Read moreThe importance of thermal fluids simulation.

Read moreHow ‘noise chambers’ help Perkins build quieter engines.

Read moreThe global voice for agricultural equipment manufacturers.

Read moreMeet our Vice President of facility operations.

Read moreThe customer benefits achieved through Perkins’ new connectivity solutions.

Read moreThe new Perkins global marketing and channel development director.

Read moreThings are different when it’s very, very cold.

Read moreEngineering manager Graham Hill explains the importance of structural simulation when designing a new engine.

Read moreThe platform will cover two key power nodes.

Read moreInterview with Susterre CEO Michael Cully on the latest no-till soil solutions.

Read moreA compact 12 cylinder powerhouse.

Read moreFor 60 years Lindner has chosen Perkins engines to power its machines.

Read moreTwo new auxiliary engines powering the marine sector.

Read morePerkins kicks off Project Coeus to demonstrate leading-edge hydrogen hybrid power solutions.

Read moreDependable electric power generation drives sales of Perkins® 4000 Series in India.

Read morePerkins launches the next generation 2600 Series engine.

Read moreAdding to the product range with an 18-litre engine.

Read moreFind out how this vast country approaches agriculture and food production.

Read moreBy re-examining, reimagining, and re-engineering what is expected.

Read moreA clear demonstration of what's possible when a passion for innovation meets a commitment to excellence.

Read moreWith local resources and global support.

Read moreAdvance power solutions from Perkins.

Read morePart three of our series with Dave Robinson.

Read moreJaz Gill talks Perkins new brand strategy.

Read moreThe Perkins® 5000 Series engines generating reliable power for critical applications.

Read moreRental expert Dave Stollery gives his view on the opportunities around rolling out EU Stage V equipment.

Read moreIf you want to get back to engineering, this programme can be the key to making it happen.

Read moreConstantly innovating to meet the changing electric power marketplace.

Read moreAn appropriate environmental, social and governance (ESG) proposition really matters.

Read moreManufacturing industrial engines at our Curitiba facility since 2003.

Read morePerkins Aurangabad celebrates the production of its 10,000th 4000 Series engine.

Read moreThe heart of sustainable power.

Read moreWacker Neuson’s new EW100 10-ton mobile excavator

Read moreOffering a complete solution for off-highway engines in Latin America.

Read moreFifty years of support for the written word in agriculture.

Read morePerkins rental industry commitment continues to grow.

Read moreRenewable and low carbon intensity fuels in Perkins engines.

Read moreSupporting the STEM development of future generations.

Learn MorePart 2 of our three part interview series with Perkins’ Dave Robinson.

Read moreThe launch of the complete range of 5000 Series full authority electronic engines.

Read morePerkins is actively supporting the rental industry's transition to the latest EU Stage V technologies.

Read morePowered by the compact and powerful Perkins® 904 Series.

Read morePerkins EAME business development director Dave Robinson writes on 'power on the farm'.

Read moreThe Perkins Rental Support Programme has already been adopted in some form by virtually every significant rental business in the world.

Read moreDid you know that Türkiye is the world’s fourth-biggest tractor market? Take a closer look – from an agricultural perspective – at this fascinating country.

Read moreThe Perkins® 904 Series family of Industrial Open Power Units provide customers with ‘plug-and-play’ engines that often can be fitted to a broad range of equipment.

Read moreThe Curitiba plant has delivered more than 300,000 engines since 2003 including engines meeting MAR-1 emission standards.

Read moreWhy the popularity of telehandlers is reaching new heights.

Read moreWhy data has become a priceless commodity in modern construction.

Read moreTalk of reaching ‘net zero’ is frequently discussed, but what does net zero look like for agriculture?

Read moreWhy the rental industry is so well placed to support sustainability goals.

Read moreWould you buy a diesel-powered mobile phone?

Read moreDiscover more about the benefits of moving to Stage V power.

Read moreWho will be the farmer of tomorrow and what skills will they have?

Read moreWhat role will this industry icon play in tomorrow's industrial world?

Read moreLow noise, vibration and harshness is important to both OEMs and the end user.

Read moreInsatiable demand for data in South Africa is driving a huge growth in data centres.

Read moreWhat does urban construction look like over the next decade?

Read moreThe electric charge: how access to reliable power is fuelling prosperity across the globe.

Read morePutting the shine on sustainability.

Read morePutting people into plant.

Read moreRevolution through evolution.

Read moreCollaboration: in search of excellence.

Read moreThe future of diesel-driven power generation keeps getting brighter.

Read moreWhat are the key benefits of downsizing engine capacity in the materials handling.

Read moreHow can manufacturing businesses move stock like clockwork?

Read moreImportant information and tips to make the best decision for your next job.

Read more