That’s the thinking behind Perkins’ Project Coeus, an exciting, wide-ranging Perkins initiative that’s been developed to help customers in the off-highway industry as they navigate the evolving energy landscape.

The journey to a more sustainable future will also create a more resilient energy system, reducing our reliance on fuels such as diesel and ‘spreading the load’ across a range of alternative fuel sources, all with improved sustainability credentials.

Thus Project Coeus. Named after the Greek god of resolve and intelligence and partially supported by a £11.14m UK government grant through the Advanced Propulsion Centre, Coeus sees Perkins partner with UK engineering expertise: Loughborough University’s Wolfson School of Mechanical, Electrical and Manufacturing Engineering, and e-powertrain specialists Equipmake.

Launched in October 2023, the three-and-a-half-year project is built around a commitment to develop an innovative ‘drop-in’ hybrid power unit, suitable as a direct replacement for the diesel equivalent.

Powernews caught up with Paul Moore, Perkins integrated powertrain engineering manager and Project Coeus lead at a recent press briefing in London, UK, to find out more.

“This is more than just proving a concept,” Paul contends. “Perkins has always been renowned for its engines, yes, but hand-in-hand with that is the way we work with OEMs to provide a complete power solution.

“That’s especially the case for smaller OEMs, who can and do tap into Perkins’ engineering expertise in pursuit of the optimum solution.”

Paul explains that the majority of Perkins’ engine production volume supports a relatively narrow range of machine types. The smaller OEMs, conversely, have close to 100 different applications. “It’s difficult for them. They can struggle to adopt new technology. There are too many barriers for them to overcome.

“What Coeus seeks to do is to make it easier to adopt these new energy technologies,” he explains.

“First, we deliver ‘drop-in’ diesel performance. Then we minimise OEMs’ power system design integration demands, as well as application validation and installation (A&I) demands.”

Together, Paul says, this should help OEMs become more confident about the adoption of lower-carbon intensity power systems and thus help to speed up the transition.

It’s this thinking, too, that’s behind the decision to go not with a single alternative fuel, but with several. “We’ve got used to diesel being the dominant fuel source and, while it would be good to pivot to a single replacement fuel, in reality that’s just not going to happen.

“There’s too much global diversity in fuel supply. And by pursuing different fuels, we can create a more resilient global fuel system, one that leverages the availability and affordability of different fuels in different regions and allows customers to use different fuel types with minimal disruption to their products.”

The four fuels selected for inclusion in Project Coeus – ethanol, methanol, bio-methane and hydrogen – have one characteristic in common: they are all spark-ignited fuels. That’s important, says Paul, in creating the common combustion platform on which Coeus relies.

“We need an engine that can perform consistently, regardless of the fuel by which it’s powered,” he explains. “Whether it’s a machine in Brazil, drawing on the already well-established ethanol production infrastructure, or the same machine in Europe that’s going to be fuelled by the nascent green hydrogen industry, we want to be able to assure the customer that despite different properties, the performance characteristics will be the same.”

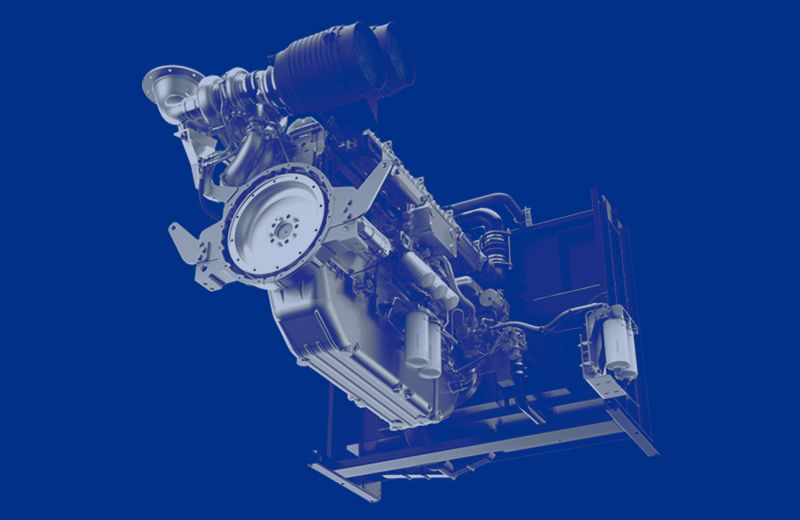

To build this advanced integrated power unit, Project Coeus brings together three key components: a spark-ignited lower-carbon intensity internal combustion platform, supported by an advanced hybrid system, both of which are managed by a highly capable digitised control system.

“Integrating these three components creates the advanced ‘drop-in’ power unit that, as far as the customer is concerned, is almost indistinguishable in interface and performance from the diesel-powered unit it seeks to supplant,” enthuses Paul. “With our advanced control systems expertise, we can build a self-optimising power unit that has the system intelligence to adapt itself, automatically, to each fuel.

“This minimises the integration engineering required. This unit’s power density, response, and so on, will be indistinguishable from a diesel-powered solution.”

The project’s being led from Perkins’ global engineering headquarters at Peterborough, in the UK. It’s just one of the 264 projects supported by the Advanced Propulsion Centre, an organisation founded in 2013 to help deliver the UK government’s aspiration for net-zero transportation solutions, whether in the wider automative sector or the niche vehicle and heavy-duty sectors.

During the project’s first year, Paul says they’ve made great strides. “We’ve gone from what was a paper-based project to a real, live, functioning prototype,” he buzzes. “It’s a very exciting position to find ourselves in.”

Paul’s team chose the 1206 as the core platform on which to develop the spark ignited hybrid power unit. A long-established and well-proven engine series, the six-cylinder 1206 spark ignited engine is expected to deliver 180 kW output running on hydrogen, with up to an additional 120 kW available from the advanced hybrid system – a level the team hopes to match as engine testing gets underway during the first half of 2025.

This first prototype has been designed to run on hydrogen, making it a significant milestone in Perkins’ long history by becoming the company’s first-ever hydrogen-fuelled engine.

“We’ll then be working with Loughborough University and their world-class engine optical diagnostic capabilities, giving us an unrivalled flow of information about in-cylinder flow, gas-injection dynamics and aftertreatment,” said Paul, adding: “Together, that gives us all the information we need to embark on a fully fuel-flexible engine design.”

Then it’s time to engage Equipmake and their extensive understanding of integrating hybrid components. Established in 1997, the company’s been responsible for developing electric powertrain solutions for almost every electric future – aerospace, automotive, marine, construction, buses – with an engineering heritage derived from motorsports including Le Mans and F1.

During 2026, the plan is to match the advanced prototype with the hybrid motor generator unit, to create a full power unit that can go into real-world testing.

“We’ve yet to determine the customer application in which we’ll do that testing,” Paul says, “but it’s going to be very exciting to get it underway.

“Coeus is all about delivering a robust, trusted plug-and-play power solution that is configurable, and thus capable of providing the off-highway industry with multiple solutions, all wrapped up as one.

“With this, we’ll be continuing our tradition of pushing the boundaries of off-highway power systems, ensuring our customers can make the right choices in navigating the evolving energy landscape, with robust, future-focused solutions.”

More than just a curiosity, they offer us different routes to future food security.

Read morePerkins marine engines has an illustrious history. Meet the team behind the brand.

Read morePower systems, services and technologies engineered for efficiency, productivity and fuel flexibility will be on show.

Read moreDelivering dependable prime and standby solutions with the 13 litre 2606 and a 46 litre 5012.

Read morePerkins has announced a power uplift to the popular 3.6 litre variant.

Read moreWe chat to Corey Berry following the successful showings at American Rental Association (ARA) and United Rentals exhibitions.

Read moreWe headed to Malaga, Spain, to learn more and see the machine in action.

Read moreWhat might the coming months hold? Powernews does some opinion legwork, so you don’t have to.

Read moreThe Perkins marine distributor network is there to service customers of Perkins anywhere in the world.

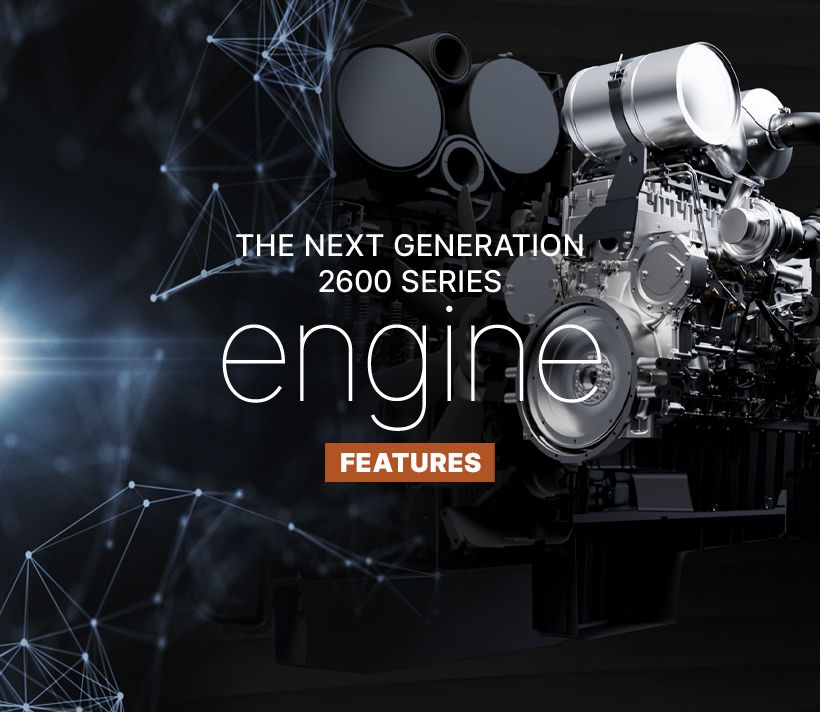

Read moreAvailable in the second half of 2025, the 2600 Series offers excellent load acceptance, fuel efficiency and versatility.

Read moreHow our Customer Solutions and Engineering teams are actively helping customers reduce fuel consumption.

Read moreThe state’s farmers grow more than 400 commodity crops, 19 of them unique to the Golden State.

Read moreMore than 280,000 visitors from across the world attended this year’s four-day long Bauma China exhibition in Shanghai.

Read moreWe follow the journey from a Perkins facility in the UK to installation on a passenger ferry in Singapore.

Read morePowernews caught up with Sylvia to learn more about her responsibilities, motivations, and leadership journey.

Read moreA new range of auxiliary marine engines were shown at METS.

Read moreAdrian Bell dives into the history of Californian agriculture.

Read moreThe importance of thermal fluids simulation.

Read moreHow ‘noise chambers’ help Perkins build quieter engines.

Read moreThe global voice for agricultural equipment manufacturers.

Read moreMeet our Vice President of facility operations.

Read moreThe customer benefits achieved through Perkins’ new connectivity solutions.

Read moreThe new Perkins global marketing and channel development director.

Read moreThings are different when it’s very, very cold.

Read moreEngineering manager Graham Hill explains the importance of structural simulation when designing a new engine.

Read moreThe platform will cover two key power nodes.

Read moreInterview with Susterre CEO Michael Cully on the latest no-till soil solutions.

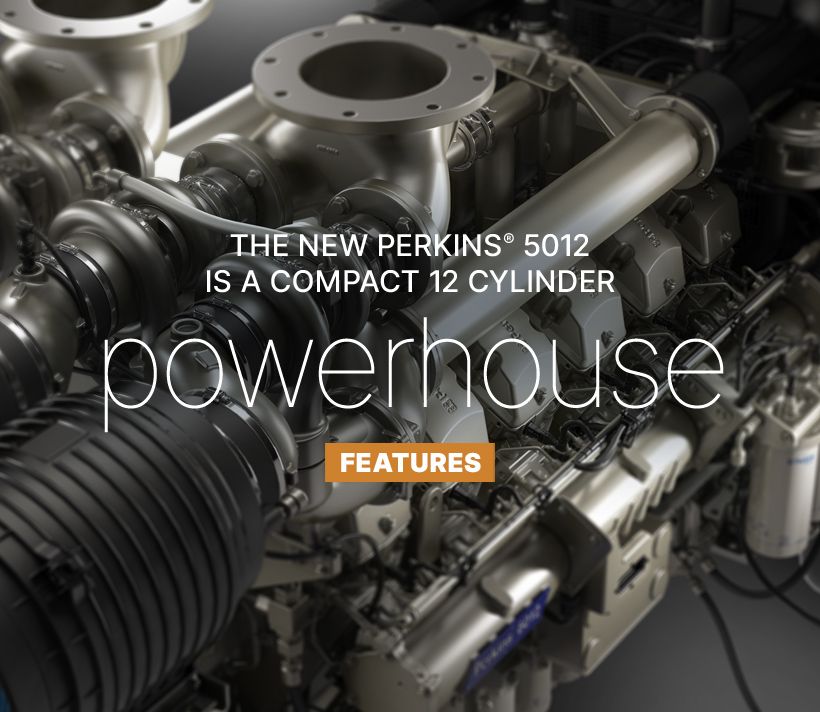

Read moreA compact 12 cylinder powerhouse.

Read moreFor 60 years Lindner has chosen Perkins engines to power its machines.

Read moreTwo new auxiliary engines powering the marine sector.

Read morePerkins kicks off Project Coeus to demonstrate leading-edge hydrogen hybrid power solutions.

Read moreDependable electric power generation drives sales of Perkins® 4000 Series in India.

Read morePerkins launches the next generation 2600 Series engine.

Read moreAdding to the product range with an 18-litre engine.

Read moreFind out how this vast country approaches agriculture and food production.

Read moreBy re-examining, reimagining, and re-engineering what is expected.

Read moreA clear demonstration of what's possible when a passion for innovation meets a commitment to excellence.

Read moreWith local resources and global support.

Read moreAdvance power solutions from Perkins.

Read morePart three of our series with Dave Robinson.

Read moreJaz Gill talks Perkins new brand strategy.

Read moreThe Perkins® 5000 Series engines generating reliable power for critical applications.

Read moreRental expert Dave Stollery gives his view on the opportunities around rolling out EU Stage V equipment.

Read moreIf you want to get back to engineering, this programme can be the key to making it happen.

Read moreConstantly innovating to meet the changing electric power marketplace.

Read moreAn appropriate environmental, social and governance (ESG) proposition really matters.

Read moreManufacturing industrial engines at our Curitiba facility since 2003.

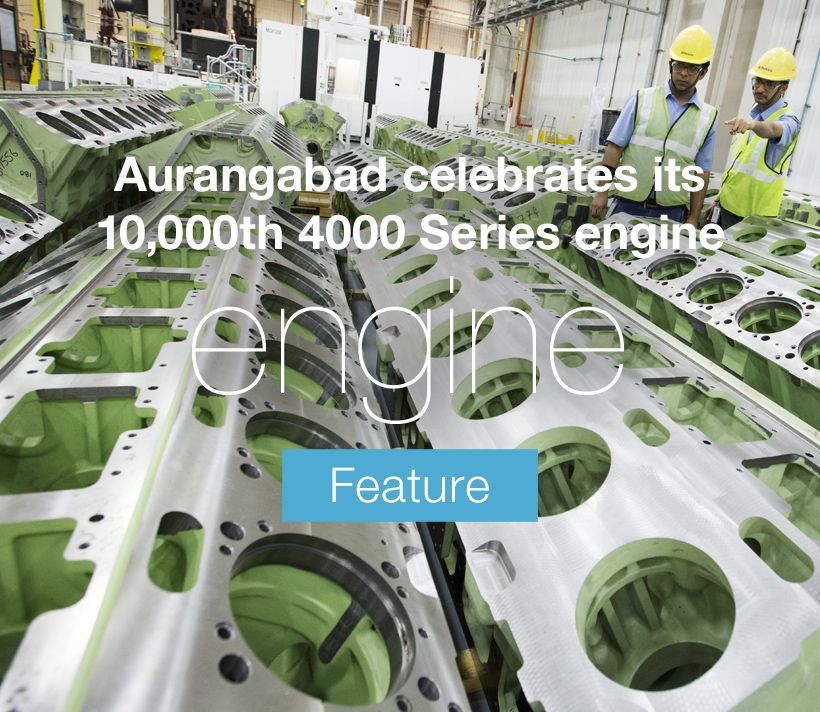

Read morePerkins Aurangabad celebrates the production of its 10,000th 4000 Series engine.

Read moreThe heart of sustainable power.

Read moreWacker Neuson’s new EW100 10-ton mobile excavator

Read moreOffering a complete solution for off-highway engines in Latin America.

Read moreFifty years of support for the written word in agriculture.

Read morePerkins rental industry commitment continues to grow.

Read moreRenewable and low carbon intensity fuels in Perkins engines.

Read moreSupporting the STEM development of future generations.

Learn MorePart 2 of our three part interview series with Perkins’ Dave Robinson.

Read moreThe launch of the complete range of 5000 Series full authority electronic engines.

Read morePerkins is actively supporting the rental industry's transition to the latest EU Stage V technologies.

Read morePowered by the compact and powerful Perkins® 904 Series.

Read morePerkins EAME business development director Dave Robinson writes on 'power on the farm'.

Read moreThe Perkins Rental Support Programme has already been adopted in some form by virtually every significant rental business in the world.

Read moreDid you know that Türkiye is the world’s fourth-biggest tractor market? Take a closer look – from an agricultural perspective – at this fascinating country.

Read moreThe Perkins® 904 Series family of Industrial Open Power Units provide customers with ‘plug-and-play’ engines that often can be fitted to a broad range of equipment.

Read moreThe Curitiba plant has delivered more than 300,000 engines since 2003 including engines meeting MAR-1 emission standards.

Read moreWhy the popularity of telehandlers is reaching new heights.

Read moreWhy data has become a priceless commodity in modern construction.

Read moreTalk of reaching ‘net zero’ is frequently discussed, but what does net zero look like for agriculture?

Read moreWhy the rental industry is so well placed to support sustainability goals.

Read moreWould you buy a diesel-powered mobile phone?

Read moreDiscover more about the benefits of moving to Stage V power.

Read moreWho will be the farmer of tomorrow and what skills will they have?

Read moreWhat role will this industry icon play in tomorrow's industrial world?

Read moreLow noise, vibration and harshness is important to both OEMs and the end user.

Read moreInsatiable demand for data in South Africa is driving a huge growth in data centres.

Read moreWhat does urban construction look like over the next decade?

Read moreThe electric charge: how access to reliable power is fuelling prosperity across the globe.

Read morePutting the shine on sustainability.

Read morePutting people into plant.

Read moreRevolution through evolution.

Read moreCollaboration: in search of excellence.

Read moreThe future of diesel-driven power generation keeps getting brighter.

Read moreWhat are the key benefits of downsizing engine capacity in the materials handling.

Read moreHow can manufacturing businesses move stock like clockwork?

Read moreImportant information and tips to make the best decision for your next job.

Read moreDelivering dependable prime and standby solutions with the 13 litre 2606 and a 46 litre 5012.

Read moreMore than just a curiosity, they offer us different routes to future food security.

Read morePerkins marine engines has an illustrious history. Meet the team behind the brand.

Read morePower systems, services and technologies engineered for efficiency, productivity and fuel flexibility will be on show.

Read more