Perkins is exhibiting a range of new:

“Partnerships promote progress,” says Jaz Gill, vice president, global sales, marketing, service and parts. “We’re a trusted partner who knows the industry inside out and truly understands the needs of customers. Their goals inspire us to innovate, which is why we work hand in hand with them to ensure their business success, today and tomorrow.

“Whether it’s optimised internal combustion, a hybrid solution or full electrification, our team of expert engineers are focused on providing power systems that are built to perform and integration services that reduce the development timescale for our customers.”

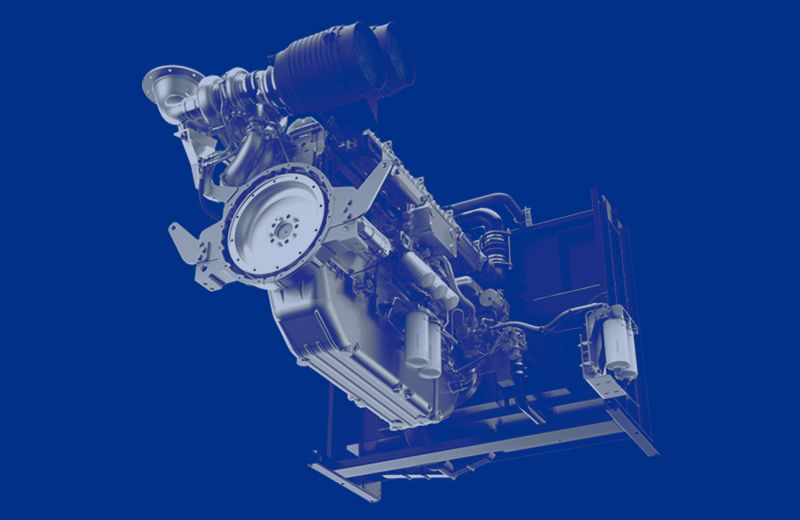

Available in 2026, the Perkins® 2600 Series engine platform is designed to meet the demands of construction and many other off-road, heavy-duty applications. The new 13-litre diesel engine platform achieves best-in-class power density, torque, fuel efficiency and productivity and extends Perkins’ leadership in high-performing, mid-sized engines with eight power ratings from 340 to 515 kW (456 to 690 hp) offering up to 3,200 Nm of peak torque. Industrial open power units configured with engine-mounted aftertreatment and cooling packs will also be available to reduce installation and validation costs for OEMs.

The 2600 Series will meet the emissions standards of highly regulated territories, such as EU Stage V, U.S. EPA Tier 4 Final, China Nonroad Stage IV, Korea Stage V, and Japan 2014, with models available for less regulated territories.

By modularising and eliminating components, its architecture is space-protected to accommodate configuration adjustments anticipated for future tiers of emission standards in the U.S. and EU without relocating customer connection points. The 2600 Series engine platform also enables the use of renewable liquid fuels such as 100% hydrotreated vegetable oil (HVO), up to B20 for models with aftertreatment and B100 for models without aftertreatment*.

The new 106 kW variant of the 904 Series platform has a 6% power uplift from the 100-kW model, and a 3% increase in torque, and is ideally suited to applications that need more power in a compact package. The standard offering from the factory also comes with EMAT aftertreatment to minimise installation costs for the OEM.

The Perkins® 904J-E36TA has been fitted with a new 12 plate oil cooler to improve the durability and reliability of the engine, while high efficiency fuel filters improve altitude capability. The engine meets Stage V, Tier 4 Final and Japan 2014 emissions standards. The 904 Series engines can be run on a wide range of fuels, subject to the fuel used meeting Perkins’ fuel specifications, including 100% HVO*.

“Perkins continues to invest in and optimise its established internal combustion engine platforms to make them even more efficient and fuel flexible,” says Jaz. “OEMs want to reduce their emissions without sacrificing power, reliability or ease of integration. The new 2600 Series and higher power 904 Series deliver high efficiency with ease of integration, helping our customers reduce their emissions without a full re-design of their machine.”

Today’s customers operate in a fast-paced world where cost-effective engine management and operational efficiency are an absolute necessity. Perkins has developed a comprehensive connectivity and condition monitoring solution to meet customers’ requirements and deliver measurable benefits to OEMs and operators.

A telematics data sharing application programming interface (API), is available for OEMs to share engine data from pre-existing OEM telematics systems, supporting equipment owners with enriched advanced analytics from the engine, supported by condition monitoring and insights that are sent to the customer’s engine support ecosystem.

Jaz explains: “Seamlessly linking to customers’ equipment, Perkins connectivity solutions improve operational control. Whether monitoring performance or optimising efficiency, the real-time insights and proactive support available from the Perkins distribution network will minimise downtime through faster service response times and an increased first-time fix rate, as well as significantly reduced costs.”

Perkins’ growing advanced power portfolio welcomes the addition of a new battery electric power unit technical demonstrator. Shown in a pipe fusion machine, the plug and play battery electric power unit is designed to enable off-highway OEMs to seamlessly transition from diesel to a battery electric powertrain.

“We’re actively helping customers navigate the shift in power system requirements, with a range of advanced power systems including electric, diesel-electric and alternative fuel compatible engines,” says Jaz.

“When it comes to the innovative fully integrated battery electric power unit, it can be ‘dropped in’ to a machine to replace a diesel engine. The system consists of a Perkins battery along with inverters, motors and on-board chargers – all packaged up into a compact drop-in system to support seamless transition from diesel to electric for our customers looking to make that move.”

The Perkins battery electric power unit has been put to the test in a McElroy TracStar® 900i pipe fusion machine as a commercial demonstrator; with the battery electric power unit replacing a 3.6 litre 904 Series diesel engine. The power unit’s compact design enables the seamless transition from diesel engine to electric, with the power unit fitting within the same chassis space and having the same mechanical connection and electrical interface points as the 3.6 litre diesel engine power unit it replaced.

Jaz continues: “This is a fully integrated battery drop-in solution, reducing the need for OEMs to invest in costly engineering and design projects and allowing them to electrify their machinery quickly and cost-effectively, without sacrificing performance. I’d encourage anyone considering the move towards electrification to talk to us about this drop-in solution which can deliver a faster return on investment, while providing the owner / operator with a low maintenance, cost-effective power solution.”

Project Coeus sees Perkins partner with e-powertrain specialists Equipmake and Loughborough University, to develop an innovative, advanced configurable-fuel drop-in hybrid power unit, as a direct replacement for a diesel engine.

The four fuels selected for inclusion in Project Coeus – ethanol, methanol, bio-methane and hydrogen – have one characteristic in common: they are all spark-ignited fuels, to create the common configurable combustion platform on which the project relies.

The first phase of the project is the development of a 180-280 kW hybrid power system, to deliver a robust and trusted fuel configurable plug and play solution that produces a consistent power performance, regardless of the fuel type, ensuring long-term flexibility for the user.

Perkins is also promoting its learnings on a diesel electric hybrid demonstrator machine that has been optimised to improve the efficiency without compromising on performance. In another project Perkins has fully electrified a technology demonstrator machine, with a Perkins Li-Ion battery.

To learn more about Perkins’ comprehensive range of power system solutions and services visit Perkins at stand A4.336 or log onto bauma 2025 | Perkins. Together we power ahead.

Why stick to one fuel, when you can have a configurable power system?

Read moreMore than just a curiosity, they offer us different routes to future food security.

Read morePerkins marine engines has an illustrious history. Meet the team behind the brand.

Read moreDelivering dependable prime and standby solutions with the 13 litre 2606 and a 46 litre 5012.

Read morePerkins has announced a power uplift to the popular 3.6 litre variant.

Read moreWe chat to Corey Berry following the successful showings at American Rental Association (ARA) and United Rentals exhibitions.

Read moreWe headed to Malaga, Spain, to learn more and see the machine in action.

Read moreWhat might the coming months hold? Powernews does some opinion legwork, so you don’t have to.

Read moreThe Perkins marine distributor network is there to service customers of Perkins anywhere in the world.

Read moreAvailable in the second half of 2025, the 2600 Series offers excellent load acceptance, fuel efficiency and versatility.

Read moreHow our Customer Solutions and Engineering teams are actively helping customers reduce fuel consumption.

Read moreThe state’s farmers grow more than 400 commodity crops, 19 of them unique to the Golden State.

Read moreMore than 280,000 visitors from across the world attended this year’s four-day long Bauma China exhibition in Shanghai.

Read moreWe follow the journey from a Perkins facility in the UK to installation on a passenger ferry in Singapore.

Read morePowernews caught up with Sylvia to learn more about her responsibilities, motivations, and leadership journey.

Read moreA new range of auxiliary marine engines were shown at METS.

Read moreAdrian Bell dives into the history of Californian agriculture.

Read moreThe importance of thermal fluids simulation.

Read moreHow ‘noise chambers’ help Perkins build quieter engines.

Read moreThe global voice for agricultural equipment manufacturers.

Read moreMeet our Vice President of facility operations.

Read moreThe customer benefits achieved through Perkins’ new connectivity solutions.

Read moreThe new Perkins global marketing and channel development director.

Read moreThings are different when it’s very, very cold.

Read moreEngineering manager Graham Hill explains the importance of structural simulation when designing a new engine.

Read moreThe platform will cover two key power nodes.

Read moreInterview with Susterre CEO Michael Cully on the latest no-till soil solutions.

Read moreA compact 12 cylinder powerhouse.

Read moreFor 60 years Lindner has chosen Perkins engines to power its machines.

Read moreTwo new auxiliary engines powering the marine sector.

Read morePerkins kicks off Project Coeus to demonstrate leading-edge hydrogen hybrid power solutions.

Read moreDependable electric power generation drives sales of Perkins® 4000 Series in India.

Read morePerkins launches the next generation 2600 Series engine.

Read moreAdding to the product range with an 18-litre engine.

Read moreFind out how this vast country approaches agriculture and food production.

Read moreBy re-examining, reimagining, and re-engineering what is expected.

Read moreA clear demonstration of what's possible when a passion for innovation meets a commitment to excellence.

Read moreWith local resources and global support.

Read moreAdvance power solutions from Perkins.

Read morePart three of our series with Dave Robinson.

Read moreJaz Gill talks Perkins new brand strategy.

Read moreThe Perkins® 5000 Series engines generating reliable power for critical applications.

Read moreRental expert Dave Stollery gives his view on the opportunities around rolling out EU Stage V equipment.

Read moreIf you want to get back to engineering, this programme can be the key to making it happen.

Read moreConstantly innovating to meet the changing electric power marketplace.

Read moreAn appropriate environmental, social and governance (ESG) proposition really matters.

Read moreManufacturing industrial engines at our Curitiba facility since 2003.

Read morePerkins Aurangabad celebrates the production of its 10,000th 4000 Series engine.

Read moreThe heart of sustainable power.

Read moreWacker Neuson’s new EW100 10-ton mobile excavator

Read moreOffering a complete solution for off-highway engines in Latin America.

Read moreFifty years of support for the written word in agriculture.

Read morePerkins rental industry commitment continues to grow.

Read moreRenewable and low carbon intensity fuels in Perkins engines.

Read moreSupporting the STEM development of future generations.

Learn MorePart 2 of our three part interview series with Perkins’ Dave Robinson.

Read moreThe launch of the complete range of 5000 Series full authority electronic engines.

Read morePerkins is actively supporting the rental industry's transition to the latest EU Stage V technologies.

Read morePowered by the compact and powerful Perkins® 904 Series.

Read morePerkins EAME business development director Dave Robinson writes on 'power on the farm'.

Read moreThe Perkins Rental Support Programme has already been adopted in some form by virtually every significant rental business in the world.

Read moreDid you know that Türkiye is the world’s fourth-biggest tractor market? Take a closer look – from an agricultural perspective – at this fascinating country.

Read moreThe Perkins® 904 Series family of Industrial Open Power Units provide customers with ‘plug-and-play’ engines that often can be fitted to a broad range of equipment.

Read moreThe Curitiba plant has delivered more than 300,000 engines since 2003 including engines meeting MAR-1 emission standards.

Read moreWhy the popularity of telehandlers is reaching new heights.

Read moreWhy data has become a priceless commodity in modern construction.

Read moreTalk of reaching ‘net zero’ is frequently discussed, but what does net zero look like for agriculture?

Read moreWhy the rental industry is so well placed to support sustainability goals.

Read moreWould you buy a diesel-powered mobile phone?

Read moreDiscover more about the benefits of moving to Stage V power.

Read moreWho will be the farmer of tomorrow and what skills will they have?

Read moreWhat role will this industry icon play in tomorrow's industrial world?

Read moreLow noise, vibration and harshness is important to both OEMs and the end user.

Read moreInsatiable demand for data in South Africa is driving a huge growth in data centres.

Read moreWhat does urban construction look like over the next decade?

Read moreThe electric charge: how access to reliable power is fuelling prosperity across the globe.

Read morePutting the shine on sustainability.

Read morePutting people into plant.

Read moreRevolution through evolution.

Read moreCollaboration: in search of excellence.

Read moreThe future of diesel-driven power generation keeps getting brighter.

Read moreWhat are the key benefits of downsizing engine capacity in the materials handling.

Read moreHow can manufacturing businesses move stock like clockwork?

Read moreImportant information and tips to make the best decision for your next job.

Read moreDelivering dependable prime and standby solutions with the 13 litre 2606 and a 46 litre 5012.

Read moreMore than just a curiosity, they offer us different routes to future food security.

Read morePerkins marine engines has an illustrious history. Meet the team behind the brand.

Read moreWhy stick to one fuel, when you can have a configurable power system?

Read more