Still family-owned, the company is managed today by Hermann and Stefan Lindner as well as the next generation, David, Christoph and Manuel. Powernews spoke with Hermann and Stefan about the secret of the company’s success.

Counter-rotating double propellers, at first glance, have little connection with agricultural engineering. But Hermann Lindner sr’s invention – while on assignment to the Air Force during the Second World War – would earn him more than just his first patent.

His lifelong enthusiasm to always achieve better results saw his Tyrolean family business produce its first tractor just three years after the end of the war. Despite its 14 bhp output, the hand-built tractor nevertheless generated huge demand, a characteristic that has remained constant ever since.

“Lindner’s 273 employees now produce over 1,200 tractors and transporters every year,” says Hermann Lindner jr, “meeting the demands of alpine mountain and grassland farming, crop farming and the municipal sector.

“My grandfather’s pioneering spirit influences all we do. In all our developments, we’re always driven by one question: how can we best support our customers in their daily work?” he explains. An objective that has sustained the company for four generations, it has inspired innovations such as continuously variable transmissions, four-wheel steering and, most recently, the TracLink digital management system.

But it’s not just determination to innovate; it’s understanding where that innovation is needed. Coming from a family of mountain farmers, Lindner sr had farming in his blood: he had the insight to understand what farmers needed. The same mentality runs through the company today.

“We remain very close to our customers,” Hermann enthuses. “A third of our employees are themselves part-time farmers. They know exactly what a tractor or transporter needs to do in the field.

“While our customers are diverse – hay milk farmers to winegrowers – what they all have in common is that they want to be quality leaders in their respective fields, so they can produce perfect products.

“For that, evidently, they need the best technology. That’s why they choose Lindner. They know they’re choosing a vehicle designed and built by farmers, for farmers.”

Lindner has undoubtedly benefited from the professionalisation of farming over the last 75 years. “Our customers are farming larger areas, they’ve become more specialised, and they’re spending more time behind the wheel,” observes Stefan Lindner.

“Sit in the same seat for 400-600 hours a year, and high driving and operating comfort becomes imperative,” he says.

“Tractors and transporters with CVT are more efficient, yes, but their popularity – more than half our machines are delivered with CVT – comes down to them being more enjoyable and less tiring to operate for hours at a time.

“Buyers also appreciate the powerful hydraulics and four-wheel steering that features on Lintrac and Unitrac. And of course, there’s the expectations of digitalisation – a perfect route for us, in terms of making customers’ work easier by deploying intelligent solutions.”

The company’s TracLink, for example, enables vehicles to recognise individual attachments, document every use of the vehicle through data and insight on status, and to steer with an accuracy of within two centimetres.

Naturally Lindner doesn’t rely solely on its own innovations to make its brand successful. At the heart of every tractor is its engine. Early Lindner models were powered by in-house designs, from a facility set up in the 1950s, but the demand for more powerful engines persuaded the company to look for a competent and efficient partner: they settled on the world’s largest manufacturer of industrial diesel engines, and a Perkins engine – a version of the venerable 3.152 that had been powering the MF35 since 1959 – was first installed in 1963 in the new BF45 model.

An immediate hit, thanks to its strong performance and innovative cooling system (the earlier Warchalowski engines were air-cooled), the BF45 was the starting signal for the Lindner-Perkins collaboration and the beginning of decades of cooperation on an equal footing. By 1972, the company had ceased production of its own engines and switched exclusively to Perkins.

“It is very important to our customers that a strong and reliable heart beats under the bonnet,” says Stefan. “From a very basic point of view, high-torque engines are particularly important on steep slopes.

“But there’s far more to our choice than that. Perkins has always had its finger on the pulse of the times, whether it’s the switch to common-rail technology or Stage V compliance. Our customers are increasingly looking for sustainable solutions, whether they’re in organic farming or municipalities, so the clean and economical Stage V engines – as featured in the switched Lintrac LS series and the Unitrac series – hold special appeal.”

Choosing Perkins marks a key differentiator for Lindner, he says. “Our continuous focus on innovation, to meet the needs of our customers, was, is, and always will be the basis for our successful development.

“Add to that the fact we remain a family business: that means long-term development, rather than short-term gain, is our top priority. But it also gives us an ability to make decisions faster: we can react more flexibly to market changes, to customer feedback, to retailer intelligence, while pursuing the sustainable, long-term business strategy that meets our customers’ expectations.

“Taken together, we can look for and capture niches in the industry that are not served by the big players.”

And while Perkins is itself a ‘big player’, it hasn’t prevented a close and ongoing collaboration with Lindner. “Perkins gives us the opportunity to actively co-develop the engines,” reveals Hermann.

“We are a niche player in more ways than one. Think about the average altitude at which our machines operate: for Perkins, we test how engines perform when they’re in operation at 1,000m above sea level.

“Then there’s our dealers. Of course, it’s important to us that our dealers know exactly how the engines work and are always up to date. We emphasise training, so things like the Perkins Electronic Service Tool help the workshops make short work of troubleshooting. Servicing and repairs can be completed much more quickly when they have access to these tools.”

Ultimately, the success of the collaboration comes down to a similar mindset: always looking ahead and delivering the best results, thinks Stefan. “Our own challenges mirror those of our customers: how can we match their increasing professionalism and help them get more out of our tractors and transporters?

“For example, many customers who currently drive a Geotrac 134ep want to increase both performance and payload. So we’ve set ourselves our own challenge: optimising the interaction between the engine and the transmission, to eke out even better performance.

“Then there’s e-fuels, too. We’ve already tested the first Perkins engines with e-fuels, and we’re excited. Very promising results give us cause to look to the future with optimism,” he concludes.

“Perkins itself believes in the same secret of success as we do here at Lindner: be very close to your customers.”

Why stick to one fuel, when you can have a configurable power system?

Read moreMore than just a curiosity, they offer us different routes to future food security.

Read morePerkins marine engines has an illustrious history. Meet the team behind the brand.

Read morePower systems, services and technologies engineered for efficiency, productivity and fuel flexibility will be on show.

Read moreDelivering dependable prime and standby solutions with the 13 litre 2606 and a 46 litre 5012.

Read morePerkins has announced a power uplift to the popular 3.6 litre variant.

Read moreWe chat to Corey Berry following the successful showings at American Rental Association (ARA) and United Rentals exhibitions.

Read moreWe headed to Malaga, Spain, to learn more and see the machine in action.

Read moreWhat might the coming months hold? Powernews does some opinion legwork, so you don’t have to.

Read moreThe Perkins marine distributor network is there to service customers of Perkins anywhere in the world.

Read moreAvailable in the second half of 2025, the 2600 Series offers excellent load acceptance, fuel efficiency and versatility.

Read moreHow our Customer Solutions and Engineering teams are actively helping customers reduce fuel consumption.

Read moreThe state’s farmers grow more than 400 commodity crops, 19 of them unique to the Golden State.

Read moreMore than 280,000 visitors from across the world attended this year’s four-day long Bauma China exhibition in Shanghai.

Read moreWe follow the journey from a Perkins facility in the UK to installation on a passenger ferry in Singapore.

Read morePowernews caught up with Sylvia to learn more about her responsibilities, motivations, and leadership journey.

Read moreA new range of auxiliary marine engines were shown at METS.

Read moreAdrian Bell dives into the history of Californian agriculture.

Read moreThe importance of thermal fluids simulation.

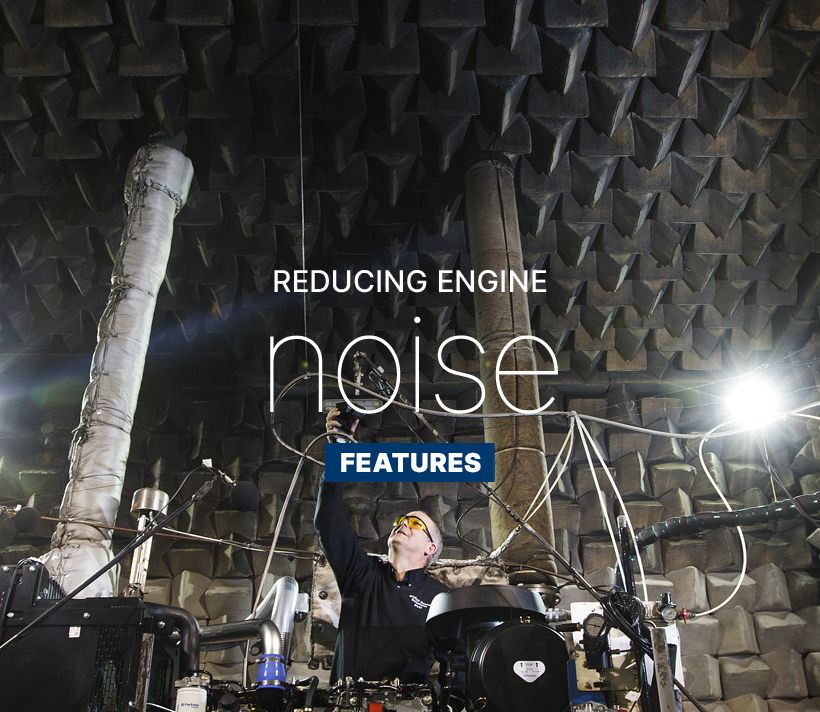

Read moreHow ‘noise chambers’ help Perkins build quieter engines.

Read moreThe global voice for agricultural equipment manufacturers.

Read moreMeet our Vice President of facility operations.

Read moreThe customer benefits achieved through Perkins’ new connectivity solutions.

Read moreThe new Perkins global marketing and channel development director.

Read moreThings are different when it’s very, very cold.

Read moreEngineering manager Graham Hill explains the importance of structural simulation when designing a new engine.

Read moreThe platform will cover two key power nodes.

Read moreInterview with Susterre CEO Michael Cully on the latest no-till soil solutions.

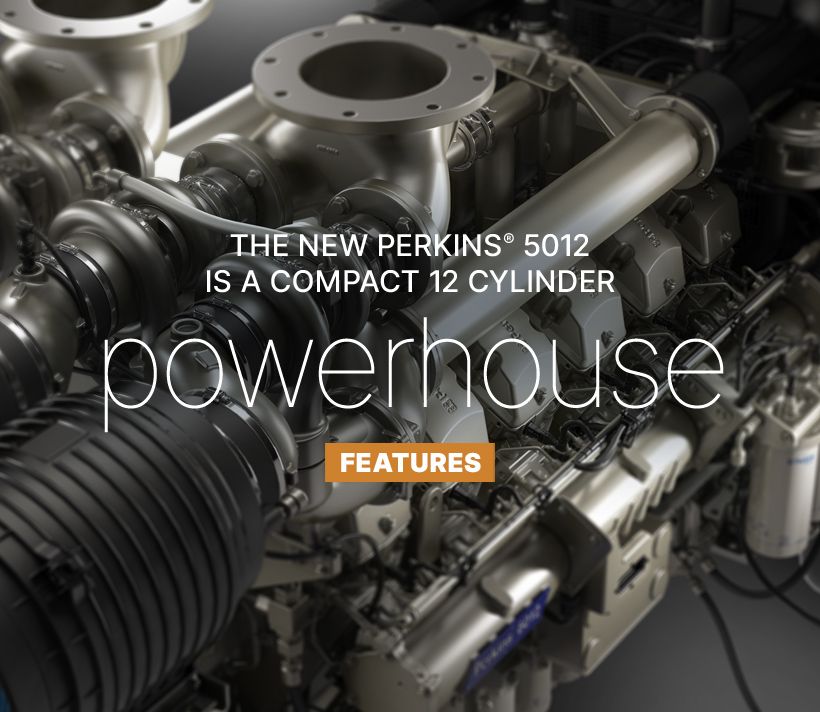

Read moreA compact 12 cylinder powerhouse.

Read moreTwo new auxiliary engines powering the marine sector.

Read morePerkins kicks off Project Coeus to demonstrate leading-edge hydrogen hybrid power solutions.

Read moreDependable electric power generation drives sales of Perkins® 4000 Series in India.

Read morePerkins launches the next generation 2600 Series engine.

Read moreAdding to the product range with an 18-litre engine.

Read moreFind out how this vast country approaches agriculture and food production.

Read moreBy re-examining, reimagining, and re-engineering what is expected.

Read moreA clear demonstration of what's possible when a passion for innovation meets a commitment to excellence.

Read moreWith local resources and global support.

Read moreAdvance power solutions from Perkins.

Read morePart three of our series with Dave Robinson.

Read moreJaz Gill talks Perkins new brand strategy.

Read moreThe Perkins® 5000 Series engines generating reliable power for critical applications.

Read moreRental expert Dave Stollery gives his view on the opportunities around rolling out EU Stage V equipment.

Read moreIf you want to get back to engineering, this programme can be the key to making it happen.

Read moreConstantly innovating to meet the changing electric power marketplace.

Read moreAn appropriate environmental, social and governance (ESG) proposition really matters.

Read moreManufacturing industrial engines at our Curitiba facility since 2003.

Read morePerkins Aurangabad celebrates the production of its 10,000th 4000 Series engine.

Read moreThe heart of sustainable power.

Read moreWacker Neuson’s new EW100 10-ton mobile excavator

Read moreOffering a complete solution for off-highway engines in Latin America.

Read moreFifty years of support for the written word in agriculture.

Read morePerkins rental industry commitment continues to grow.

Read moreRenewable and low carbon intensity fuels in Perkins engines.

Read moreSupporting the STEM development of future generations.

Learn MorePart 2 of our three part interview series with Perkins’ Dave Robinson.

Read moreThe launch of the complete range of 5000 Series full authority electronic engines.

Read morePerkins is actively supporting the rental industry's transition to the latest EU Stage V technologies.

Read morePowered by the compact and powerful Perkins® 904 Series.

Read morePerkins EAME business development director Dave Robinson writes on 'power on the farm'.

Read moreThe Perkins Rental Support Programme has already been adopted in some form by virtually every significant rental business in the world.

Read moreDid you know that Türkiye is the world’s fourth-biggest tractor market? Take a closer look – from an agricultural perspective – at this fascinating country.

Read moreThe Perkins® 904 Series family of Industrial Open Power Units provide customers with ‘plug-and-play’ engines that often can be fitted to a broad range of equipment.

Read moreThe Curitiba plant has delivered more than 300,000 engines since 2003 including engines meeting MAR-1 emission standards.

Read moreWhy the popularity of telehandlers is reaching new heights.

Read moreWhy data has become a priceless commodity in modern construction.

Read moreTalk of reaching ‘net zero’ is frequently discussed, but what does net zero look like for agriculture?

Read moreWhy the rental industry is so well placed to support sustainability goals.

Read moreWould you buy a diesel-powered mobile phone?

Read moreDiscover more about the benefits of moving to Stage V power.

Read moreWho will be the farmer of tomorrow and what skills will they have?

Read moreWhat role will this industry icon play in tomorrow's industrial world?

Read moreLow noise, vibration and harshness is important to both OEMs and the end user.

Read moreInsatiable demand for data in South Africa is driving a huge growth in data centres.

Read moreWhat does urban construction look like over the next decade?

Read moreThe electric charge: how access to reliable power is fuelling prosperity across the globe.

Read morePutting the shine on sustainability.

Read morePutting people into plant.

Read moreRevolution through evolution.

Read moreCollaboration: in search of excellence.

Read moreThe future of diesel-driven power generation keeps getting brighter.

Read moreWhat are the key benefits of downsizing engine capacity in the materials handling.

Read moreHow can manufacturing businesses move stock like clockwork?

Read moreImportant information and tips to make the best decision for your next job.

Read moreThe customer benefits achieved through Perkins’ new connectivity solutions.

Read moreThe new Perkins global marketing and channel development director.

Read moreThings are different when it’s very, very cold.

Read moreEngineering manager Graham Hill explains the importance of structural simulation when designing a new engine.

Read moreThe platform will cover two key power nodes.

Read moreInterview with Susterre CEO Michael Cully on the latest no-till soil solutions.

Read moreA compact 12 cylinder powerhouse.

Read more